Footprint

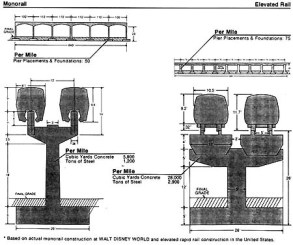

For compatibility reasons, Bombardier kept the standard Disney beam way size, used at Disneyland, of 26″ (660mm) wide by 48″ (1.22m) in the middle and 80″ (2.03m) at the ends. These precast, pre-stressed girders are between 90 and 110 feet (27.4m to 33.5m) in length. They have a hollow center core to keep the weights under 50 tons. Some of the girders have some combination of vertical and horizontal curvature). The minimum curve radius is 250 ft (76.2m). Compare the Disney beam way to a typical elevated standard rail (4’8.5″ [1.435m] gauge).

The piers per mile count is 50 with monorail, whereas in standard rail the pier count is 75. Also notice the per-mile amounts of steel and concrete required for both monorail and light rail: 4.6 times the concrete and 2.4 times the steel, not to mention the aesthetics.

Dual beam guide ways are on 12′ centers. To conform with modern transit standards, Bombardier has added an optional emergency evacuation walkway to the design, although it has not been retrofitted to Disney World.

Suspension

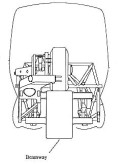

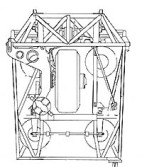

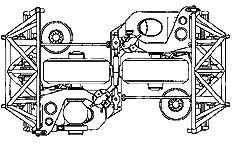

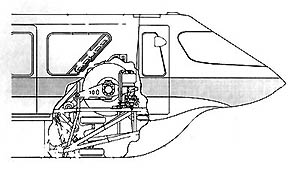

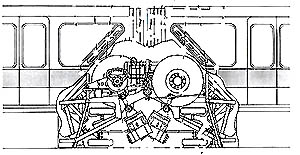

The Mark trains use a slightly different bogie scheme than the Seattle ALWEG and Hitachi ALWEG monorails. Where the Seattle and Hitachi trains have independent bogies that have load wheels that extend into the cars, the Mark III/V, Mark IV and Mark VI trains have load wheels at the ends of the cars, which are attached to the substructure. Also, instead of two tires per axle on the Seattle and Hitachi trains, there is only one on the Mark III/V, IV and VI trains.

These load tires are 445/65R22.5 Michelin XTE2 46.6″ diameter , 17.8″ wide truck tires, the same ones you can see on a dump truck or cement mixer. The tires are nitrogen-filled to reduce the possibility of fire.

They also have run-flat capability. These tires will last 100,000 miles in normal operation. Maximum rated speed for these tires is 65 mph (105 km/h). The load capacity of these tires are 12,800 pounds (5806 kg) each at maximum inflation. There are 12 load tires per 6 car train and 48 guide tires per 6 car train.

These guide tires are 21.5″ in diameter. In addition, there are two steering wheel tires under each cab car to help steer the suspension up to 3 degrees in either direction. Steering is accomplished in the intermediate cars by the relative geometry of the two adjacent cars.

Thus, all 12 load tires are steerable, and the tires are always tangent to the curve. The main suspension of the cars above the axles is done with air bags (also called air springs). The air bags are automatically inflated/deflated by a leveling valve, which allows varying load conditions. There are also vertical hydraulic shock absorbers.

Propulsion, Braking & Power

The Mark VI trains have eight 100hp, 600-volt DC electric motors. These motors also act as brakes by turning the motors into generators and dissipating the power into resistor banks between each car. This is called regenerative braking. Each of the twelve load tires has an 18-inch mechanical disk brake, but the mechanical system generally accounts for less than 1/4th the braking required in normal operation. The dynamic braking slows the train to about 13 mph. Top speed of the Mark VI trains is 55 mph, but the standard operating speed at Walt Disney World is 40 mph.

The Mark VI trains have eight 100hp, 600-volt DC electric motors. These motors also act as brakes by turning the motors into generators and dissipating the power into resistor banks between each car. This is called regenerative braking. Each of the twelve load tires has an 18-inch mechanical disk brake, but the mechanical system generally accounts for less than 1/4th the braking required in normal operation. The dynamic braking slows the train to about 13 mph. Top speed of the Mark VI trains is 55 mph, but the standard operating speed at Walt Disney World is 40 mph.

The propulsion system is called the “Propulsion and Dynamic Braking (P/DB) System.” There are two redundant P/DB systems per train, and either is capable of running the train. Each train consumes 138 KWH (kilowatt hours) per operating hour. This translates into a per-train mile of 10.78 KWH, or 0.13 KWH per passenger mile. Power is applied to the traction motors in steps to keep current consumption within the proper limits. Acceleration is 1 mph/s, deceleration is 0.44 mph/s.

The propulsion system is called the “Propulsion and Dynamic Braking (P/DB) System.” There are two redundant P/DB systems per train, and either is capable of running the train. Each train consumes 138 KWH (kilowatt hours) per operating hour. This translates into a per-train mile of 10.78 KWH, or 0.13 KWH per passenger mile. Power is applied to the traction motors in steps to keep current consumption within the proper limits. Acceleration is 1 mph/s, deceleration is 0.44 mph/s.

Rolling Stock

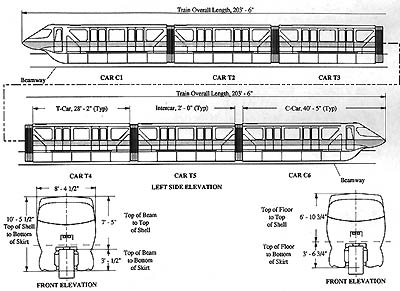

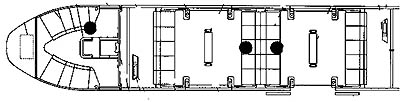

Mark VI trains are 203’6″ long (62m). Cab cars are 40’5″ (12.3m) long and intermediate cars are 28’2″ (8.6m). Inner-car distance is 2′ (.61m). Width is 8’4.5″ (2.55m), and interior height is 6’10.75″ (2.1m). The bottom skirt extends 3’6.75″ (1.09m) from the top of the floor. The car body is made of composite shells, and they sit on top of square and round tubing-based truss assemblies (see diagrams).

Each car has 4 doors, two on each side. The trains are fully air conditioned. Each Mark VI car can carry 20 passengers seated and 40 passengers standing. Thus, each train can carry 360 people.

Each car has 4 doors, two on each side. The trains are fully air conditioned. Each Mark VI car can carry 20 passengers seated and 40 passengers standing. Thus, each train can carry 360 people.

Switching

Low cost pivot switches are typically used in the yard and maintenance area. These typically operate in 50 seconds. High-speed (10 seconds) beam replacement switches are used for branching and merging.

Towing and Storing

In the event of a breakdown, a diesel powered tow tractor can be attached to either end of the monorail to pull or push it along the track to the maintenance shed.

The Roundhouse maintenance shed can hold 10 of the 12 monorail trains. The remaining two trains are stored in the Contemporary hotel or at the Transportation and Ticket Center over night.

Monorail Yellow and Monorail Red parked at the T&TC over night.

(Source: Monorail Society)